“Blows of hammers blare in the valley. A thick black smoke glides above the forest. Some nights a week, strange lights light the sky.

In small careers of limestones located in the side of the mountainside of the calcareous blocks of the rocky wall are extracted. These blocks are then crushed and prepare for the transport for the oven with lime. Big trees are slaughtered and of the firewood is picked up. Raw materials are transported to the oven with lime where reigns an intense activity.

We are in Roman epoch, in 65 before JC. The Romans introduced the lime as equipment of building into our regions, his production is made in an almost industrial way. The lime is used in the building as sociable, dissolved in the water it serves as a basis for the manufacture of mortar and of concrete. It is also used to whiten walls.

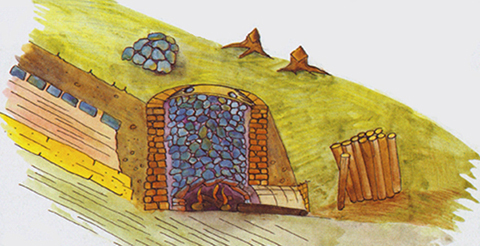

Workers construct the oven in one be several metres deep, do a gallery of heating there and set up a strong arch which must carry about 20 tons of calcareous rocks. Circulation of air is envisaged and the calcareous rocks are put down with caution in several layers in the oven.

The fire is finally lighted after several days of exhausting job. As soon as the embers illuminate the arch, the men stir the late because the limestone must remain in a temperature about 1000 °. Plunged into the clouds of smoke, they cover the oven of straw and of a layer of humid loam, regulating so in an uninterrupted way the’ circulation of air. The fire must be fed regularly during two days and three nights, when it uses about 30 cubic metres of wood.

At the end of cooking, the oven must get cold during several days. Finally, chauliers can pick the fruits of their labour. They extract porous and light white pieces of quicklime of the still lukewarm oven. There is not more than about the half of the mass of initial calcareous stone. The lime is crushed in powder and transported towards the construction sites of building. The oven is prepared for a new cooking.”

The relics of the lime furnace of Senningen tell us however another story: the fire was put out in a premature way and the process of calcination was stopped. Was it further to a wooden lack’, was it due to the too much wet wood, was it further to a seepage of water during a big storm or further to a collapse of the arch of the oven? All job was in vain. The partly calcined lime, reacted with water and humidity and knitted together in a big inert block. The relics of the oven were protected by its rocky tomb during almost two millenniums, it was only discovered in 1938 during work of road building.

The relics of the lime furnace of Senningen tell us however another story: the fire was put out in a premature way and the process of calcination was stopped. Was it further to a wooden lack’, was it due to the too much wet wood, was it further to a seepage of water during a big storm or further to a collapse of the arch of the oven? All job was in vain. The partly calcined lime, reacted with water and humidity and knitted together in a big inert block. The relics of the oven were protected by its rocky tomb during almost two millenniums, it was only discovered in 1938 during work of road building.